|

Cangzhou Zhongtuo Cold Forming Equipment Co., Ltd.

|

2022 good quality steel door frame roll forming machine from zhongtuo Machine

| Price: | 15000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

One 20ft or 40ft container for loading one set machine with manual decoiler.

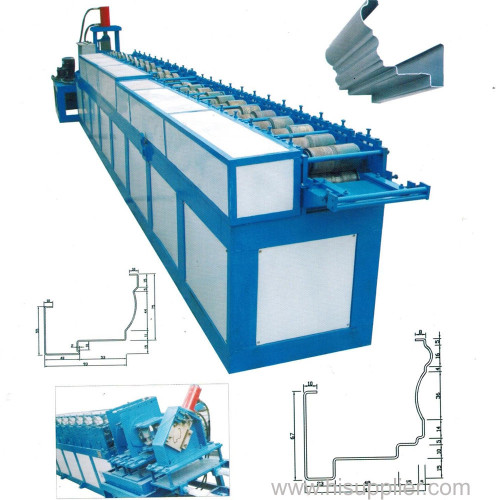

2022 good quality steel door frame roll forming machine from Zhongtuo Machine

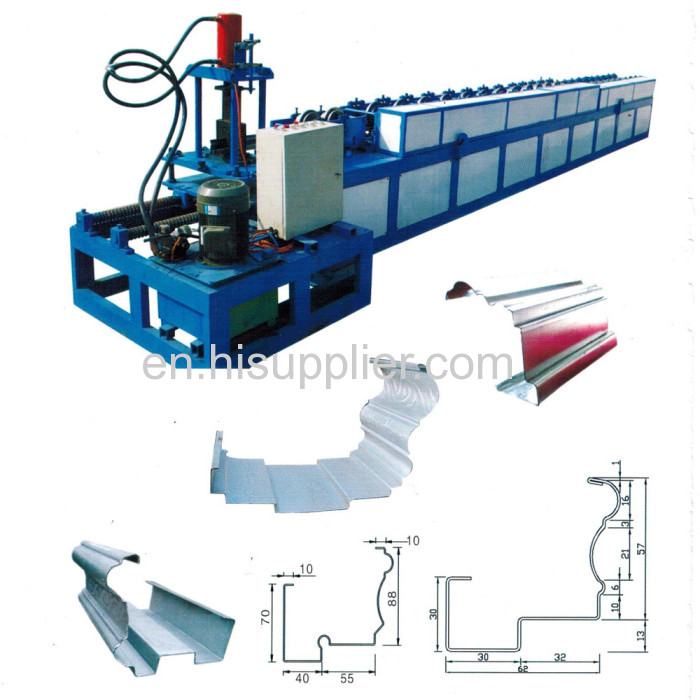

Steel door frame roll forming machine is designed to roll form the galvanized steel to the door frame or window frame shape. Normally the thickness of the door frame or window frame is from 0.65mm to 1.0mm. Our steel door frame roll forming machine is widely used in the steel door or steel window manufacturing. Steel door frame roll forming machine consists of uncoile, leveler, mail roll forming machine, cutting part, runout table, PLC control box and hydraulic station. The whole machine are controlled by the industrial PLC, which can gurantee the machine work automatically and precison of the final products.

1. Steel door frame roll forming machine Processing flow:

Manual de coiler→Guide roller→Feeding material →Leveling→punching→roll forming→strengthening→Hydraulic cutting→product receiving table

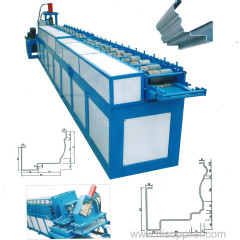

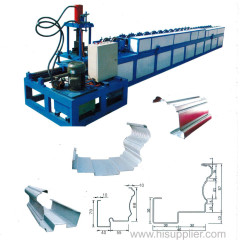

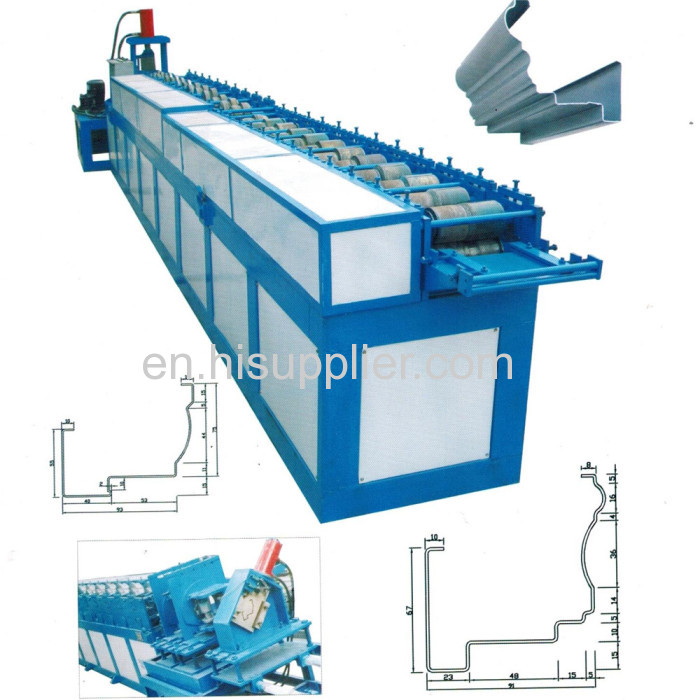

2. Steel door frame roll forming machine Profile drawing:

Our steel door frame roll forming machine is customized, we can design the machine as customers' personal requirements. Customer can send us samples or send us the profile drawing of the door frame or window. Here below I attached some door frame profile drawings for you reference, if you have this machine demand, please let me know your personal requirements and then I can prepare a machine proposal for you.

Other related products profile drawing for you reference:

3. Steel door frame roll forming machine Technical parameters:

Configurations | manual decoiler, feeding, Punching, main machine of roll forming, cutting part, hydraulic station, Delta PLC control system, run out table | |||||

Material | Raw material | Galvanized | ||||

Thickness | 0.65-1mm | |||||

Material hardness: | 550 MPA---350 MPA | |||||

Manual decoiler | Inner Diameter: 450-550mm | Expand by manual | ||||

Max Coil width:300mm | ||||||

Capacity: 3T | ||||||

Main Forming machine | Forming steps | 16stations | ||||

Shaft diameter | 50mm | |||||

Design type | middle plate welded,Memorial arch frame type | |||||

Frame thickness | 25mm | |||||

roller material | GCr12MoV | |||||

shaft material | 45# steel with tempering | |||||

Work speed | 0-15m/min | |||||

Transport | By gear | |||||

Power of main machine | 5.5 kw | |||||

Hydraulic cutting and punching system | Power supply | Hydraulic station | ||||

punching mould material | GCr12MoV | |||||

Blade mould material | GCr12MoV | |||||

no distorting or wasting. High level safety factor. | ||||||

Hydraulic system | Hydraulic oil | 46# | ||||

Power | 3kw | |||||

Cutting length | As required | |||||

No distorting or wasting. High level safety factor. | ||||||

Control Device | control | By PLC | ||||

PLC language | English and Chinese (or as required) | |||||

Screen | Touch screen | |||||

Function | Automatic length ,punching and quantity measurement | |||||

Other Spare part | Weight | About 3 ton | ||||

Dimension | 4300*800*1400mm L*W*H | |||||

Main body color | As you need | |||||

Voltage | 380v/50hz/3ph(or as required) | |||||

Spare cutting blade | One piece | |||||

Fuse | 2 pieces | |||||

Relay | 2 pieces | |||||

Travel switch | 2 pieces | |||||

Solenoid valve | 1 pieces | |||||

Terms of payment | 1. 30%T/T ,Balance to be paid before shipping after inspection. 2.Deliver time: 35 working days. | |||||

Warranty and Training | 1. Warranty: Support the technology all the life. And the machine broken because of quality, we can change the broken part for free within one year. 2. Training: If you come to our factory,we can teach you for free. If you need technician go foreign, the buyer need pay the cost for visa, hotel, ticket, food and others, and buyer need pay the technician USD50/day for salary. There need one technician. Training time will be one week. | |||||

.jpg)

.jpg)