|

Cangzhou Zhongtuo Cold Forming Equipment Co., Ltd.

|

Main Runner Main Tee Bar of Suspended Ceiling Grid rolling forming machine

| Price: | 15000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

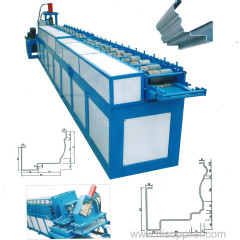

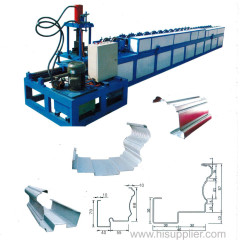

Main Runner/Main Tee Bar of Suspended Ceiling Grid rolling forming machine

Main Runner/Main Tee Bar of Suspended Ceiling Grid offers maximum economy, simplicity and accessibility. Its hot-dipped, galvanized steel construction provides corrosion resistance and ensures paint adhesion. Working together with USG ceilings panels, they form the fastest-installing ceiling systems in the industry. Normally the system has main runner main T bar and cross T bar and wall angle. Here I will show the main T drawing profile for your reference:

As to the punching part and connection design, we can make according to the customer drawing. Ceiling installation is easy with the quick-release cross tee clip. The clips are easy to remove without tools, minimizing tee damage. And an audible click when securing tee-to-tee connections ensures accuracy. Normally the machine use the material of galvanized steel and color steel. Based on those knowledge and requirements, we make the machine like this:

Main Runner/Main Tee Bar of Suspended Ceiling Grid rolling forming machine features:

1. As to the rolling machine part, we design with accurate rollers to make sure the size 100% accurate.

2. The important part lies in the punching, we design using the whole punching system. The it can make sure the punching position more accurate.

3. Whole length punching, one pieces we do the punching by one time, so the speed is fast and position is accurate.

4. With gas push and cables, we can make the cable and wire orderly.

5. Use the big hydraulic station to make sure the punching is non-stop.

.jpg)

.jpg)